Cryogenic Handling

General Remarks

Handling cryogenic liquids should only be done by trained people. The following instruction are by no means a replacement for a certified cryogenics course. They are meant as a reference for how to handle cryogenics at the Neutron guide hall.

Fear is a bad teacher

and you should always consult a more experienced instrument scientist or the sample environment team,

if you are in doubt how to handle things correctly.

Please always keep in mind that you are working with boiling liquids which will evaporate rather quickly when exposed to ambient temperatures.

Think about the consequences of your doing before you do it (e.g. what will happen if you open a specific valve).

For information on how to set up an orange cryostat and how to change samples, please follow this link: OrangeCryostat . .

Liquid Nitrogen

Most of our cryostats and cryo-magnets have an outer liquid nitrogen jacket to reduce the heat load on the helium bath.

The storage dewars are prepared by the sample environment staff and can be picked up at the preparation area (between FOCUS and MARS).

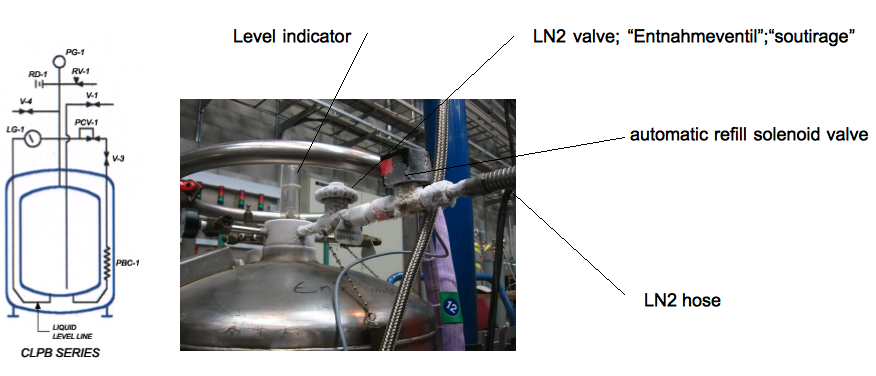

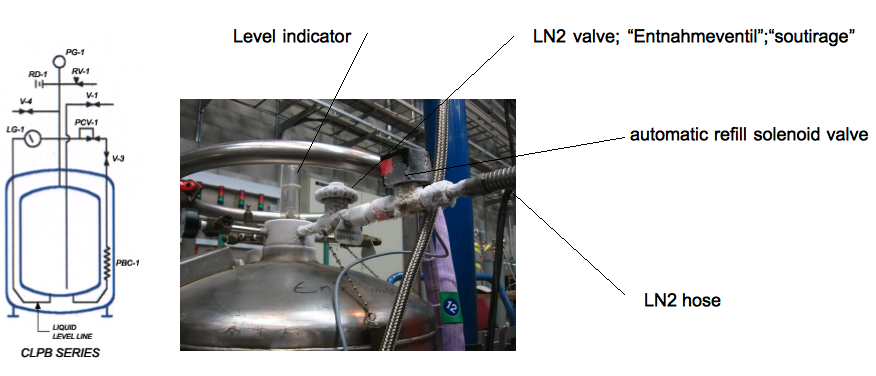

The dewars provided are self pressurizing systems with a mechanical level indicator at the top as shown below.

The dewars are always pressurized.

- Ensure that the hose is firmly connected to the vessel and the nozzle is not pointing towards a person before opening the valve.

The filling hoses have a metallic protection sleeve. The valves and the hose get very cold during a nitrogen transfer.

- Make sure that you wear protective leather gloves when handling cold parts, however the gloves should never be soaked with LN2 or LHe.

When using the automatic nitrogen refill

- test the automatic to assure that the filling hose remains in the cryostat filling port and that the system switches off correctly

Liquid Helium

Liquid Helium dewars are provided by the sample environment staff at the preparation area.

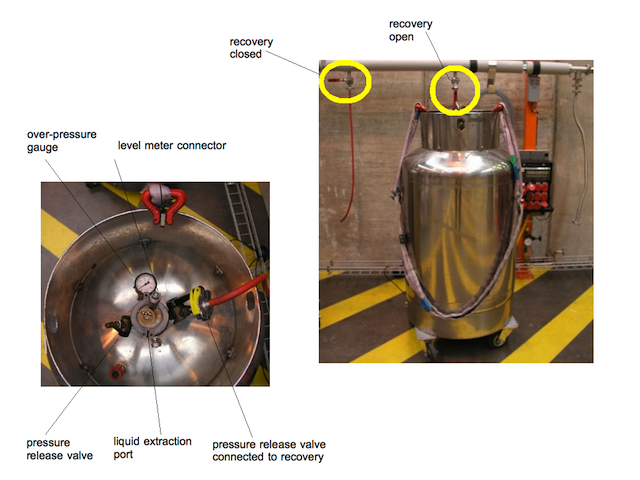

At PSI we run a Helium recovery system.

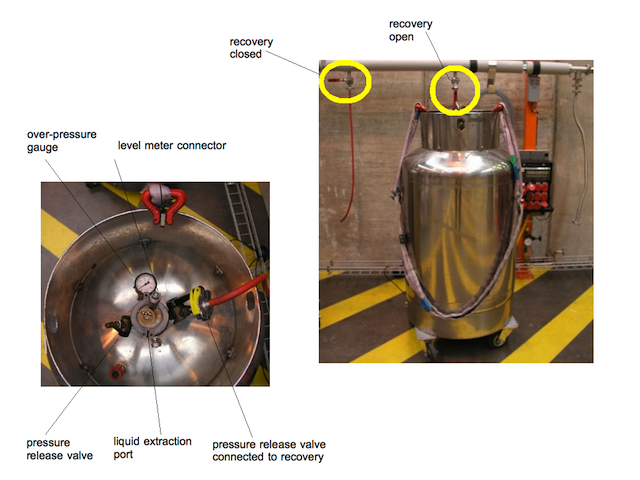

- Please make sure that the dewars are always connected to the recovery line when not in use

- Remember to close the valve on the recovery line when taking a dewar away and to open it after return

- The Level meter in the preparation area shows the level in litres. Make sure that there is sufficient helium for filling. The dewars

should be returned with a level of at least 10-15 litres.

- When using the crane be aware that no equipment (or dewar) should be moved over the DMC detector

Helium Dewar Transport:

Helium dewars are brought into the experimental area with the 1T crane.

- Only instructed people are allowed to use the crane. (A short training is offered by the LDM mechanics personal.)

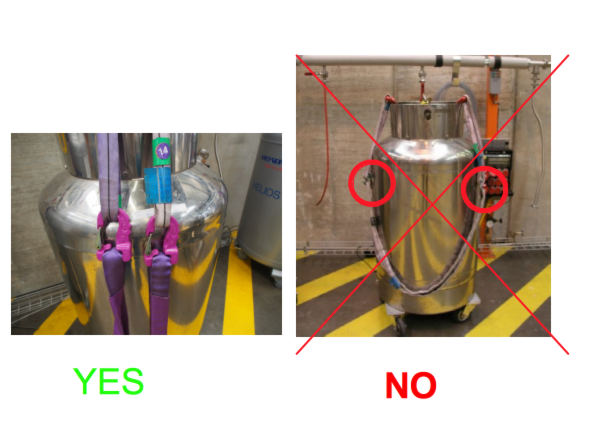

- Only dewars with pre-installed transport straps are allowed for crane transportation.

- To extend the straps please use the proper extensions as shown in the picture below.

Helium Transfer:

- Before you open the extraction port you should release the pressure in the dewar which might have built up during transport by opening one of the release valves

- Insert the Helium siphon first into the transport dewar.

- close all manual pressure release valves

- slowly lower the siphon into the dewar and observe the pressure rise in the dewar (try to stay below 0.2bar)

- you should see gas streaming out on the other end of the siphon

- don't put your hands in the gas stream

- when it starts to turn white you can insert this end into the cryostat Helium filling port

- continue to lower the siphon into the transport dewar until you reach the bottom.

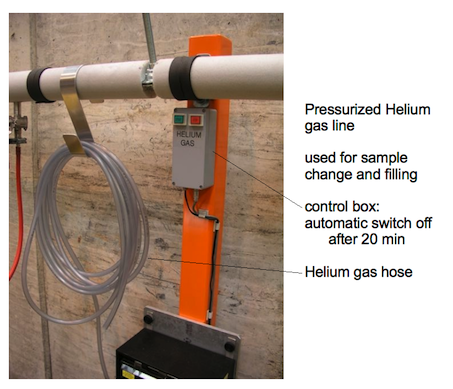

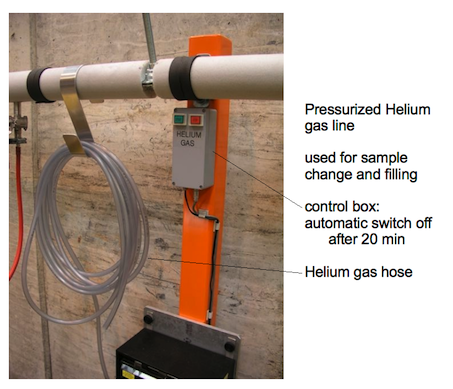

- switch on the compressed Helium gas line and connect the gas hose to one of the pressure release valves

and open it. The dewar is now pressurized to 0.15 bar over pressure.

- make sure not to empty the vessel completely, the people running the liquefier will love you. On the transfer line, normally there is a prolongation with a hole at 10 cm above the end. If not, you should lift the transfer line by 10 cm after inserting.

When the transfer is finished:

- stop the pressure line

- release the dewar pressure before you remove the siphon.

- make sure that the extraction and filling ports are properly sealed. It might be necessary to

use a hair dryer to remove the ice.

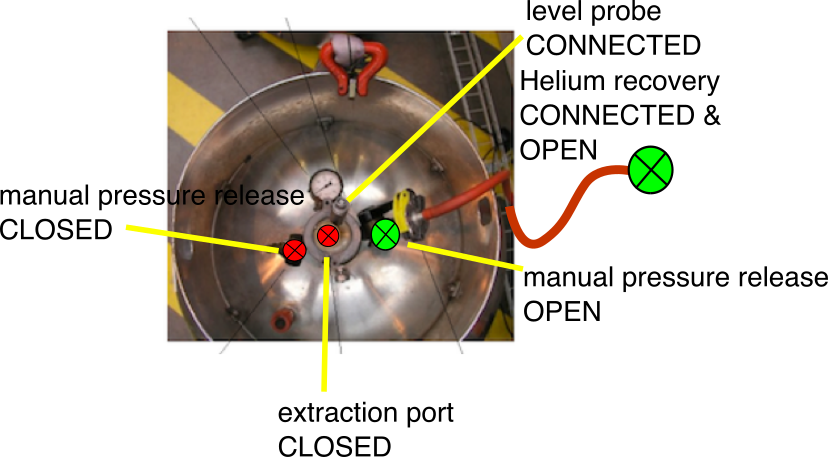

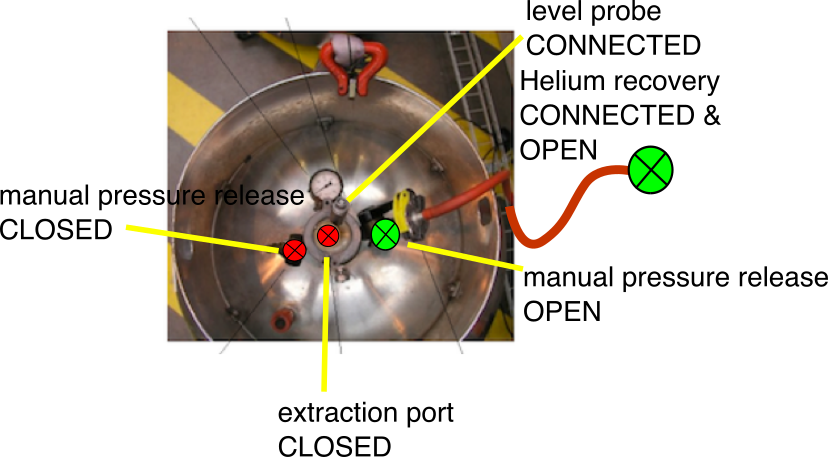

Returning Liquid Helium Dewars

please return dewars to the dewar station as soon as possible after the transfer

- connect the dewar to the rubber hose of the dewar station

- open the manual valve to the recovery

- open the manual pressure release that is connected to the recovery on the dewar

- check the other manual pressure release. it MUST be closed

- retighten the locking nut of the Helium extraction port

- connect the level probe

IMPORTANT:

recheck that all valves are in the right state and the level is reading before you leave

In case you are unsure about certain procedures, please contact sample environment staff

Attachments:

HeDewar.png

gasline.png

CCU.png

transportstraps.png

afterfill.png

cl_clpb.gif

LN2.png

HeDewartransport.png

Printer Friendly

Page Info

This page last changed on 25-Nov-2016 12:56:42 UTC by 129.129.156.72.

|

LIN

LIN