|

This is version 12.

It is not the current version, and thus it cannot be edited.

[Back to current version]

[Restore this version]

Condensing the Mixture

- Fill the cold trap with liquid nitrogen and make sure that

both traps are in the dewar

- Make sure that all tubes are connected correctly

- Cool the 1 K pot to a temperature below 3 K. With the

Variox 2 K may be reached, with MA09 about 2.5 K.

Open the needle valve to get a pressure at the 65 m3

pump of about 20 mbar.

- Open the valves in the pumping line and in

the condenser line.

- Open the green valve marked "out" below the dump. The dump is the

grey cylinder in the center of the gas handling system rack.

- Switch on the 3He pump (while pressing on the 3He button, press

RAISE).

- Make sure that the heater on the mixing chamber is off and that

the setpoint is zero. Switch off the still heater also.

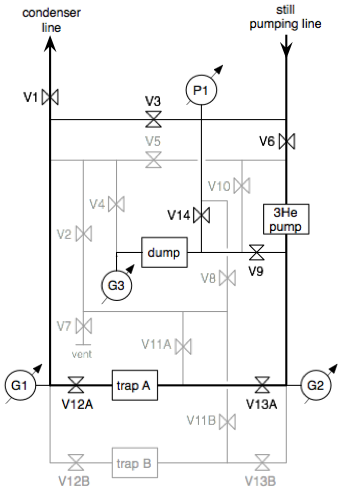

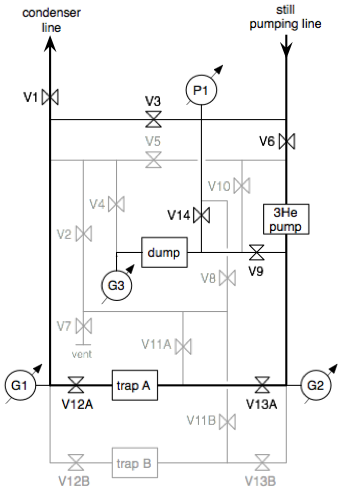

- Open valve 9 (while pressing on the valve button, press

RAISE).

- The reading on G2 is proportional to the amout of mixture in the

dump. It should read something around 660(DIL1) or 400(DIL2) mbar.

- Open valves 1 and 6 (Valve 6 is a motor valve, while pressing

the red valve button, press RAISE until a value of 99.9 is shown).

- Open valve 13A

- Open a little valve 12A (4.0 % to start).

- While the pressure reading on G1 should always be below about 400 mbar,

Valve 12A can bae opened gradually, and opened completely, when the

reading on G2 drops below 350 mbar.

- During condensation, the 1 K pot temperature might raise to more than 3 K,

especially when the pressure on G1 is high. Adjusting the needle valve

is only necessary, when this temperature get too high and prevents

the condensation to progress.

- After some time (depends on the temperature of the mix. chamber)

the mixing chamber should reach about 1 K, and then

the pressure on G1 stabilizes at a low value.

Now you may start to pump out the dump: close valve 9,

and open valve 14 for a short time

(close it when P1 raises above 50 mbar).

As soon as the pressure on P1 drops down, you might open

and close valve 14 again, but make sure that the pressure on G1 does

not increase above 350 mbar.

- At some stage, when opening valve 14, the pressure on P1 does no longer

raise above 50 mbar. Leave the valve open until the P1 drops below 0.1.

- The temperature in the mixing chamber goes down in steps during the

condensation process. It takes some time until the temperatures start

to move downwards, and goes then quickly below 1 K. Then it stays there

or decreases slowly to about 0.8 K, for about half an hour or more, before

going down by more than 0.01 K per minute.

- Once the temperature has stabilized in the region of 0.1 K or less,

the flow on the condenser line might falls below 100 (black display below

the valve panel).

Setting the still heater to a power of 3-5 mW, the flow can be increased

back to about 100, and the temperature should go down more. Good luck!

This particular version was published on 10-Jun-2008 11:35:07 UTC by MarkusZolliker.

|

|

LIN

LIN